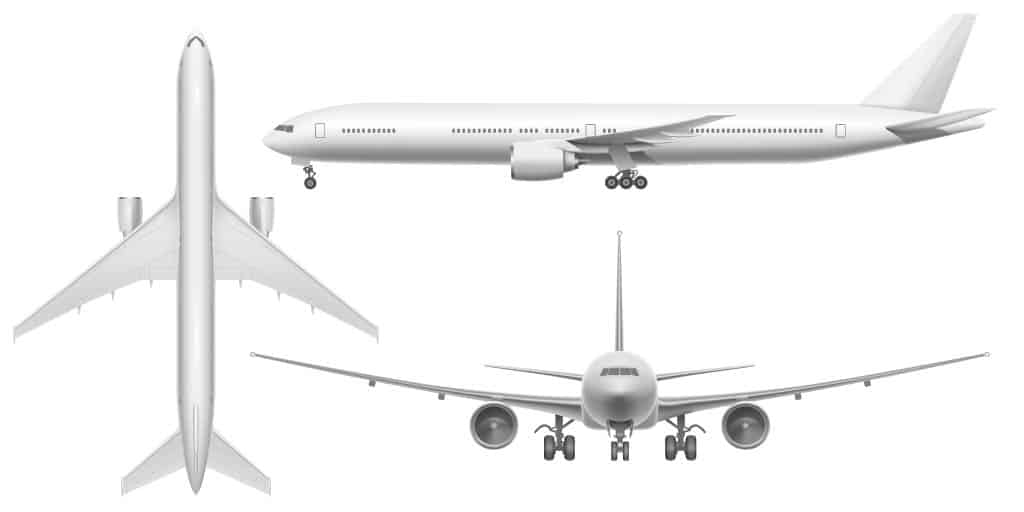

An aircraft looks and operates like one enormous machine. However, it’s actually made up of several parts that are designed to work seamlessly in unison. Without even one of those parts, the airplane would be unable to perform optimally, if at all. Material planning is crucial to be able to gather and order the parts necessary for each airplane to operate efficiently. Additionally, whether you’re studying for the AFOQT or simply want to learn more about how planes are designed, having a grasp of the main parts of an aircraft is basic and essential knowledge. To understand the purpose and importance of each of the aircraft components, it’s easiest to break them down into five main categories. The five main aircraft components include the powerplant, empennage, landing gear, fuselage, and wings. Keep reading to learn more about each part’s unique function.

An aircraft looks and operates like one enormous machine. However, it’s actually made up of several parts that are designed to work seamlessly in unison. Without even one of those parts, the airplane would be unable to perform optimally, if at all. Material planning is crucial to be able to gather and order the parts necessary for each airplane to operate efficiently. Additionally, whether you’re studying for the AFOQT or simply want to learn more about how planes are designed, having a grasp of the main parts of an aircraft is basic and essential knowledge. To understand the purpose and importance of each of the aircraft components, it’s easiest to break them down into five main categories. The five main aircraft components include the powerplant, empennage, landing gear, fuselage, and wings. Keep reading to learn more about each part’s unique function.

Powerplant

Everything that involves powering the airplane so that it can ascend, descend, and move forward falls into this category. It includes the plane’s electrical network and engine, normally situated beneath the wings if more than one. Some may consider the fuel system as an aspect of the powerplant, too, since the engines depend on it to work, but technically, the fuel tanks are usually located inside the wings. If the aircraft has a propeller, it would be regarded as part of the powerplant as well.

Empennage

Referring to the tail, the entire empennage is made up of several smaller components. It has a vertical stabilizer, also known as a fin, which is a slab that angles up and outward, away from the body of the plane. Within the vertical stabilizer is a rudder, essential for controlling flight direction. Using foot pedals, the pilot can steer the rudder left or right.

There’s also the horizontal stabilizer, appearing like two smaller wings on either side of the vertical stabilizer. It includes an elevator toward the rear. The pilot controls it by pulling on a yoke in the cockpit to make the nose of the aircraft move up or down. Some aircraft use a stabilator instead of a horizontal stabilizer. Also called an all-moving or all-flying tail, it lets the pilot accomplish the same task with less strain or risk of overcorrecting.

No empennage would be complete without the trim tabs, which are connected to the trailing ends of both the vertical and horizontal stabilizers. Small and rectangular, they’re meant to stabilize the airplane’s movement by influencing the surrounding air pressure. Trim tabs are included in stabilators as well.

Landing Gear

An aircraft has to land eventually, and landing gear is the component that lets them do so safely. An aircraft can have several different types of landing gear. Most commonly, they’re made up of struts and wheels, but some planes use floats if they’re expecting to land on water, or skis if they need to glide to a stop on top of snow. Either way, the pilot can control them with a disc brake.

For single-engine planes that use wheels, they’re usually divided into a single wheel close to the nose and a pair of wheels nearer the tail. These are called tricycle gear. Some small aircrafts, typically taildraggers, use two wheels neighboring the nose and one beneath the tail, known as conventional landing gear. Like other types of landing gear, they can be handled with a disc brake.

Fuselage

The fuselage is basically considered to be the main body of the airplane. It stretches from one end to the other, large enough to contain the pilot’s cockpit at the front and gradually tightening as it approaches the tail. Within the cockpit, an aircraft hydraulic system is installed so that the pilot can control all the other main parts of the aircraft. Typically hollow, the fuselage is the perfect place to install seats for passengers, as well as an area to store luggage or other objects.

Wings

Attached to either side of the fuselage, the wings make it possible for an aircraft to lift itself through the air and glide or turn steadily. It’s also not uncommon for wings to place winglets on the tips to help with lifting. Each wing consists of a network of metal ribs, stringers, and spars encased in aluminum, fabric, or a composite material, usually made up of Kevlar and glass or carbon fibers.

Lift dumpers or spoilers are situated on the top surfaces of each wing, designed to lift on hinges to disturb the surrounding airflow. This may prompt the airplane to roll clockwise or counterclockwise, depending on which spoiler is activated.

The wings are divided into two smaller components–the leading edge and the trailing edge. Slats built into the leading edges can increase or decrease the overall surface area of the wings, generating or reducing lift as necessary for takeoff or landing.

In the space on the trailing edge nearest to the fuselage, flaps are installed to perform the same function as the slats. Close to the tips of the trailing edges, there are the rectangular ailerons. By manipulating the airflow around one wing or the other, the ailerons determine whether or where the aircraft turns.

What Else is Important to an Aircraft’s Design?

Although every airplane should have some combination of these components in order to function as intended, the materials from which they’re made factor into their performance. When they’re made of metal, they must be strong enough to withstand various levels of air pressure but lightweight enough to let the machine fly efficiently. This is why aluminum is a common choice, but heavier metals, such as titanium and steel, have been known to be used as well.

In recent years, however, composite materials are gaining favor. Both glass and carbon fiber offer the same advantages as aluminum, plus a few more. More specifically, they’re even tougher and lighter than aluminum, and they’re resistant to rust and stress, which are common problems for metal. The only real disadvantage to using glass or carbon fiber is that they’re more expensive. However, for many designers, pilots, and passengers, the peace of mind could be well worth the extra cost.

In addition to all this, an aircraft requires pressurization, oxygen, heating, and cooling systems to allow the pilots and passengers to breathe and remain comfortable at high altitudes. The pressurization system relies on pumps built into the exterior of the plane to bring fresh air inside, as well as an outflow valve at the tail to let used air leave. Some of the air is passed through a hot compressor to provide heat when it’s released into the fuselage. Since the outside air gets colder at high altitudes, the aircraft also needs deicing and anti-icing systems to remove ice or keep it from forming. Otherwise, the aircraft parts will become too frozen to work.

Overall, an airplane is a complex machine. Each of these parts and components can be further broken down into even smaller parts and components. Albeit, knowing the most basic and essential aspects of aircraft design is the best way to begin understanding the fine details.

Propel Yourself with Proponent

Proponent is an independent aerospace distributor that offers over 500,000 priced aircraft components and parts, delivered on time, all around the world. Proponent is dedicated to meeting your business’s needs and does so by offering understanding customer service from industry experts. Contact Proponent today to learn more.

Learn more