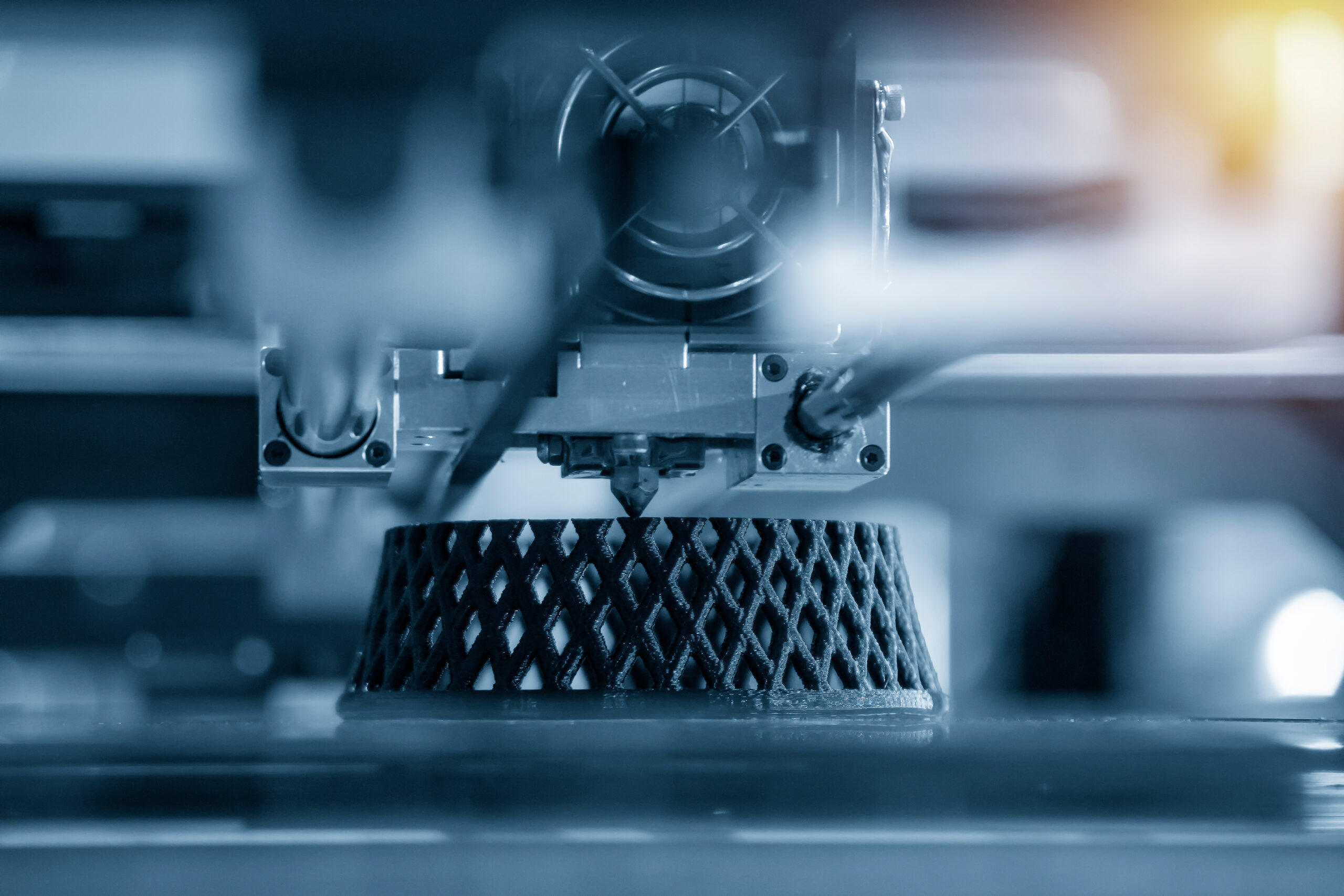

Believe it or not, but the future involves printing out parts for airplanes. 3D printing—also known as additive manufacturing—is revolutionizing the aviation and aerospace industries by transforming how components are made. With a 3D printer, engineers can create lightweight parts, rapid prototypes, and complex components that traditional manufacturing can’t easily produce. Printing these parts is faster and can reduce the weight of the parts and lower production costs. Additive manufacturing is making building aircraft more efficient and environmentally friendly.

Read on to learn more about how 3D printing is being used in aviation and aerospace.

Evolution of Additive Manufacturing in Aerospace Applications

3D printing has been used in aviation for longer than you might think, and its predecessors have been around for even longer. Here’s the history of 3D printing in aerospace at a glance:

- 1981: Though additive manufacturing predates modern aerospace, its roots trace back to early rapid-prototyping systems in the 1980s—such as Dr. Hideo Kodama’s first rapid prototyping machines that created parts layer by layer.

- 1986: Chuck Hull, the inventor of 3D printing, files the first patent for stereolithography (SLA), the predecessor to modern 3D printing.

- 2011: The University of Southampton showcased the first entirely 3D-printed airplane.

- 2014: SpaceX flew flight-critical hardware featuring a 3D-printed main oxidizer valve in its Falcon 9 engine.

- 2014: SpaceX’s 3D-printed SuperDraco engine reached qualification and became the first fully printed rocket engine.

- 2017: The Electron rocket launched with a nearly entirely 3D-printed engine; orbital success followed in 2018.

- 2022: Collins Aerospace created an Additive Manufacturing Center to implement 3D printing part creation.

- 2023: Relativity Space pushed boundaries with its Terran 1 rocket: the first 3D printed rocket to reach space.

Key Applications of 3D Printing in Aviation

As you can see from the history of additive manufacturing, 3D printing is well ingrained in aviation and aerospace. Its ability to help engineers create durable, lightweight components makes it a very versatile tool. Below are some of the most impactful ways it’s being applied.

Rapid Prototyping and Design Validation

One of the earliest and still most valuable applications of 3D printing in aviation is rapid prototyping. Engineers can quickly produce test models and design iterations to evaluate fit, form, and function within hours or days instead of weeks. The ability to prototype and test quickly reduces time-to-market for new aerospace technologies, faster innovation, and more efficient product development cycles.

Production of Complex Engine Components

Additive manufacturing allows aerospace engineers to design and fabricate intricate engine components that are difficult or impossible to create with traditional methods. Components like fuel nozzles, turbine blades, and combustion chambers can be printed as single, consolidated units with advanced internal geometries. This can improve fuel efficiency and thermal performance while also increasing durability and reducing overall engine weight.

Custom Tooling

3D printing gives engineers on-demand creation of tools, jigs, and fixtures that are precisely tailored to the needs of individual manufacturing processes. These custom tools help speed up assembly lines, improve worker ergonomics, and reduce errors. Compared to conventional machining, 3D-printed tooling can be produced faster and at significantly lower cost.

Maintenance, Repair, and Overhaul (MRO) Operations

Additive manufacturing is a game-changer for MRO operations in aviation. Instead of waiting weeks for replacement parts to ship from centralized warehouses, maintenance teams can print parts locally and on demand to dramatically reduce aircraft downtime. This decentralized production model also improves supply chain resilience by enabling operators to keep fleets flying even during logistical disruptions.

Mounting Brackets

3D printing is particularly effective for producing low-volume, high-strength structural brackets used to mount systems such as avionics, sensors, and ducting. These brackets are often customized to fit unique aircraft geometries and load-bearing requirements. With additive manufacturing, engineers can optimize bracket designs for both strength and weight, improving aircraft performance while simplifying the installation of complex systems.

Common Aerospace 3D Printing Materials

The success of 3D printing in aerospace heavily depends on the materials used. Below is a table summarizing some of the most common materials in aerospace additive manufacturing, their key properties, and typical applications:

| Material | Key Properties | Typical Aerospace Applications |

| Titanium Alloys (e.g., Ti-6Al-4V) | High strength-to-weight ratio, corrosion-resistant, excellent high-temperature performance | Engine components, structural brackets, and landing gear parts |

| Aluminum Alloys (e.g., AlSi10Mg) | Lightweight, good thermal and electrical conductivity, cost-effective | Airframe structures, housings, and heat exchangers |

| Inconel (e.g., Inconel 718) | Nickel-based superalloy, exceptional strength and oxidation resistance at high temps | Turbine blades, engine nozzles, combustor liners |

| Stainless Steel (e.g., 17-4 PH) | High strength and hardness, moderate corrosion resistance | Mounting brackets, tools, clamps, and interior structural supports |

| PEEK (Polyether ether ketone) | High-performance thermoplastic, lightweight, chemical and flame-resistant | Electrical insulation, ducting, cable management, cabin components |

| ULTEM (PEI – Polyetherimide) | Flame retardant, heat resistant, low outgassing | Cabin parts, UAV components, aerospace-grade enclosures |

| Carbon-Fiber Reinforced Nylon | Strong and lightweight, enhanced stiffness and dimensional stability | Prototypes, fixtures, lightweight structural components |

Benefits of 3D Printing in Aviation

3D printing is transforming aviation by offering engineering teams new levels of efficiency, flexibility, and innovation. Here are the key advantages that make 3D printing a game-changer for aerospace and aviation.

Weight Reduction and Fuel Efficiency

One of the most impactful benefits of 3D printing in aviation is weight reduction. Lighter components directly translate to better fuel efficiency and reduced carbon emissions. Engineers can redesign traditional parts with optimized geometries that maintain strength while removing unnecessary mass. For example, GE Aviation’s 3D-printed fuel nozzle for the LEAP engine is an example of how this can be a reality. When they 3D printed the component, it reduced costs and weight by over a third.

Cost Savings and Production Speed

Additive manufacturing significantly reduces production costs by minimizing material waste, reducing the need for tooling, and accelerating production timelines. Traditional subtractive methods often waste up to 90% of material when machining from blocks—whereas 3D printing builds parts layer by layer with minimal scrap. Additionally, 3D printing gives you on-demand production, which means companies can reduce inventory, lower warehousing costs, and respond quickly to changing demand.

Geometric Design Flexibility

3D printing gives you a level of design freedom that’s not feasible with conventional manufacturing. Engineers can now build parts with internal cooling channels, lattice structures, and complex geometries that optimize weight and performance. These designs often lead to topologically optimized parts that use less material while maintaining or improving strength.

For example, turbine blades with internal cooling passages, which were once impossible to manufacture using casting or machining, can now be printed directly using metal additive technologies. This improves heat dissipation, extends component life, and boosts overall engine efficiency.

Assembly Consolidation

By consolidating multi-part assemblies into single components, 3D printing dramatically simplifies the build process. Fewer parts mean less assembly time, lower labor costs, and reduced risk of failure at connection points such as bolts, welds, or fasteners. For aerospace manufacturers, this means leaner supply chains and lower logistics overhead. Fewer parts also reduce documentation requirements and makes the certification process easier.

Surface Finish and Post-Processing

Various post-processing techniques—such as polishing, heat treatment, and machining—can refine the finish to meet strict tolerance and aesthetic requirements. Technologies like Material Jetting and Direct Metal Laser Sintering (DMLS) are known for producing finer surface resolutions and can be used on 3D printed components. These advancements ensure that 3D-printed components perform well and also meet regulatory standards for flight-readiness.

Challenges in Implementing 3D Printing Technologies

While 3D printing presents significant advantages for aviation, its widespread adoption comes with some challenges. These factors must be addressed to fully integrate additive manufacturing into mainstream aerospace production.

Certification and Regulatory Considerations

Aerospace is one of the most tightly regulated industries, with rigorous certification standards for every flight-critical component. 3D-printed parts must meet the same—or higher—levels of scrutiny as traditionally manufactured parts, particularly when used in engines, airframes, or control systems. This includes extensive testing for structural integrity, fatigue life, and environmental resistance.

The lack of universally accepted standards for additive manufacturing has slowed adoption. However, organizations like SAE International, FAA, and EASA are actively working on frameworks to standardize design, testing, and quality assurance for 3D-printed aerospace parts.

Material Performance

Although 3D printing offers design freedom, not all printable materials yet meet the demanding performance criteria for aerospace applications. Some materials still fall short in areas like fatigue resistance, creep performance, and thermal stability, which are essential for high-stress or high-temperature components like turbine blades and structural mounts.

Ongoing research is focused on advancing both metal powders and high-performance polymers to deliver better in-flight performance. Innovations in alloy development and powder bed fusion techniques are helping bridge the gap, but significant testing and validation remain necessary before widespread implementation.

Availability of Materials

Aerospace-grade materials such as Ti-6Al-4V, Inconel, and PEEK are limited in availability and expensive to produce in powder or filament form. This scarcity drives up costs and adds complexity to sourcing and logistics. Moreover, not all 3D printers are compatible with these materials, limiting flexibility across production sites.

To address these barriers, aerospace companies are forming strategic partnerships with material suppliers, investing in vertically integrated supply chains, and exploring recyclable or hybrid material options.

Part Orientation

In additive manufacturing, the orientation in which a part is built directly affects its mechanical properties, especially in the Z-axis, which is typically weaker due to layer-by-layer bonding. This can lead to reduced strength and fatigue performance in critical load-bearing directions. As a result, aerospace designers must consider build orientation during the design for additive manufacturing (DfAM) phase, often requiring simulation tools to predict performance and adjust designs accordingly.

Support Structures

Support structures are essential in many additive processes to stabilize overhangs and complex geometries during printing. However, they introduce several challenges: they increase material usage, prolong post-processing time, and can affect surface smoothness and part accuracy.

To reduce dependency on supports, alternatives like Selective Laser Sintering (SLS) and Binder Jetting are being explored. These technologies allow for more complex, self-supporting designs and require minimal post-processing.

The Future of Aerospace 3D Printing

The next frontier of aerospace 3D printing is already taking shape. These are a few of the aerospace and aviation developments on the horizon:

- Advanced materials unlock new possibilities. High-strength alloys, metal matrix composites (MMCs), and carbon fiber-reinforced polymers are making 3D-printed parts stronger, lighter, and more resilient in extreme conditions. Meanwhile, nanomaterials are showing promise in improving thermal conductivity—critical for space and defense applications. These advanced materials will enable next-generation components that surpass traditional limitations in performance and durability.

- On-demand, distributed manufacturing. As aerospace OEMs and suppliers look to build more agile and resilient operations, on-demand 3D printing is emerging as a game-changer. Instead of relying on centralized warehouses with long lead times, manufacturers can produce certified parts locally or even on-site. This model is especially compelling for Maintenance, Repair, and Overhaul (MRO) environments, remote operations, or military deployments.

- Multi-material and hybrid manufacturing systems. Innovations like multi-material printing and hybrid manufacturing systems (which combine additive and subtractive processes) are paving the way for more integrated components. These technologies allow for the creation of parts with built-in electronics, gradient properties, or thermal management features.

Unmatched Reliability in Aircraft Parts Distribution

As 3D printing continues to transform aerospace manufacturing, one thing remains constant: the need for reliable, high-quality parts delivered on time and ready to perform. Whether you’re embracing additive manufacturing for innovation or maintaining legacy fleets, having a dependable distribution partner is critical to keeping your operations running smoothly.

At Proponent, we combine deep aviation expertise with a commitment to part availability, precision sourcing, and trusted logistics. From 3D-printed components to certified OEM parts, our company will make sure you get what you need.

Ready to elevate your supply chain with unmatched reliability? Explore ProCart!